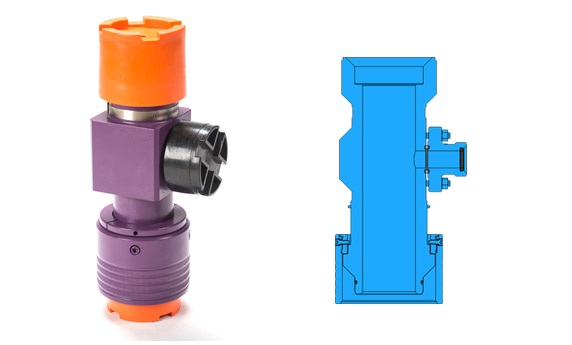

Pump in Sub

The pump in sub normally sits below a BOP and has a side access at right angles to the main bore.

Its purpose is to quickly pump large quantities of fluid into a well in the event of an emergency.

This function is a kill option on a well and can very effectively cap off it off with the hydrostatic pressure.The fluid used is generally mud with additives in it that make its density very high.

The Phuel Pump in Sub is designed to customer connection sizes, bore and side port specifications although generally a 1502 or 2202 hammer lug union is used as the side access port as the industry standard.

The side port is secured to the body via a flange arrangement that ensures a rugged and tough joint that is protective against rough treatment.

All the connections are customisable to the specified requirements and we have experience in producing a multitude of combinations.

Phuel Hi-Grip Collars as standard.