Phuel Risers (or Lubricators) are pressure-containing tubular sections with threaded or flanged connectors, essential for wireline operations. They enable the wireline tool string to be raised above the wellhead valve for wellbore entry and exit. While electric line operations typically use risers with uniform internal diameters, slickline operations can utilize varying bore sizes, with the smallest bore positioned at the top.

Lubricators

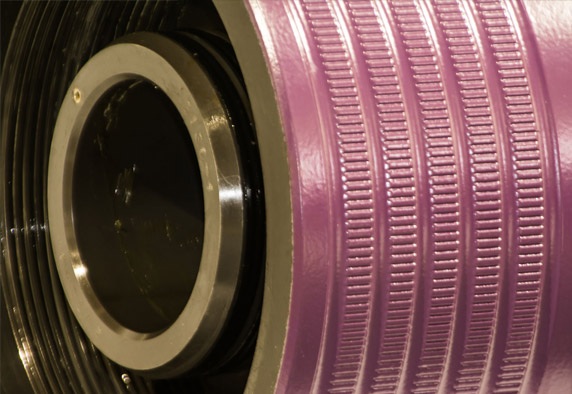

Phuel manufactures risers in two designs to suit varying needs. The Integral design, a single piece of material, is ideal for lengths up to one meter and can withstand pressures up to 15,000 PSI. For longer applications, the Multi-Piece design is utilized, consisting of three threaded sections. These sections employ robust metal-to-metal ACME sealing connections reinforced by O-rings, providing reliability for pressures up to 10,000 PSI. Both designs offer versatility with either Quick Union or Flanged end connections, ensuring compatibility with your existing stack-up and pressure requirements. Notably, for shorter riser lengths, the Integral design often presents a more cost-effective solution.

Standard Features

- Saver Sub allows easy replacement of worn or damaged pressure connections.

- Blank Saver Subs are available with no pressure port or we can supply these c/w ‘Autoclave’ ports for the high pressure applications

- Industry standard Flange or Quick Union end connections to suit your requirements

- Body connections incorporate low torque metal seal with O-ring back up for easy maintenance

- Split Body Option – suitable for working pressures up to 10,000 PSI

- One-piece Body – for shorter lengths and working pressures up to 15,000 PSI

- Phuel Safe Lok Collar System is standard and allows the Collar to be supported while stabbing in

Let’s talk about your project.

If you have any requirements or need further information, please don’t hesitate to contact us.

All our products can also be rented through Robust Rental