The Phuel Modular Wireline Blowout Preventer (BOP) combines the latest manufacturing techniques with innovative design to provide the ultimate in flexibility, practicality and performance.

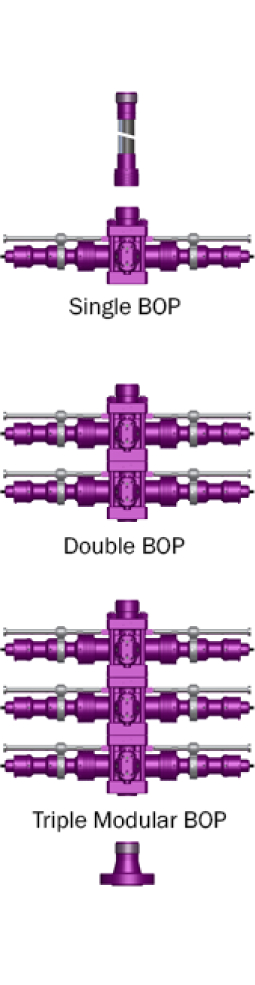

Modular Wireline Blowout Preventer (BOP)

Technical overview

Available with 3”, 4-1/16”, 5-1/8”, 6-3/8”, 6-5/8” and 7-3/8″ bores for 10K and 15K working pressures

Multi-seals that seal to 10,000 psi from blind to 15/32 slammer cable

Integral ram guides that centralise the wire as the rams close every time

Ram position indicator rods

Support bars for the actuators in all sizes to reduce manual handling requirements

Replaceable valve seats on all equalising valves for improved reliability

Modules include equalisation valve and grease/glycol injection valve

Lightweight when compared to mono-block BOPs

Phuel High Grip Collars

Product details

Individual modules can be combined to form dual, triple, quad or quin configurations. The joining of the modules is achieved with a low height segment connection that provides safe and reliable connecting without adding any of the extra height that traditional single BOP stacking incurs.

The flexibility continues with the top and bottom connections. These are connected in the same manner as the bodies allowing you to set the assembly up exactly how you need it with Flange or Quick Unions.

All Phuel Modular BOPs have been extensively tested and qualified. Testing has been completed in accordance with API 16A (witnessed by a third party authority) involving fatigue, temperature and functional testing including shearing and guiding of all wire sizes. The BOPs are certified to API 16A, 6A and meet the requirements of Norsok D-002.

Let’s talk about your project.

If you have any requirements or need further information, please don’t hesitate to contact us.

All our products can also be rented through Robust Rental