Gripper Sub

Designed to reduce risk when dealing with wire /cable problems, the Gripper provides a secure anchor point supporting the weight of the Tool String reducing the risk of damage to the BOP Inner Seals.

In the past, it has been acceptable to close a Dual (inverted) BOP over the wire and establish a grease seal, then rig down the lubricators above it to complete the repair. Although common practıce, this means that work is being done with only one barrier against well pressure – normally operating requirements state at least two independent barriers.

The use of two Dual (inverted) BOPs can resolve the barrier issue but due to the nature of wire problems the repair normally means cutting the wire below the problem resulting in the BOPs having to support the weight of the Tool String, something that BOPs are NOT designed to do.

Relying on a BOP to support the Tool String weight to allow for a rig down is dangerous, even if the BOP/BOPs manage initially to support the Tool String weight whilst providing the pressure barriers there is no guarantee that this will continue.

If the gripping function were to fail during this period, then the seals of both the well barriers would be simultaneously compromised by the stripping actıon of the wire through the inner seals. This could lead to the loss of control of well pressure.

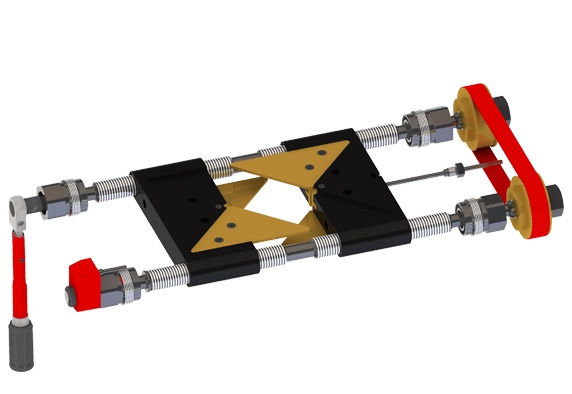

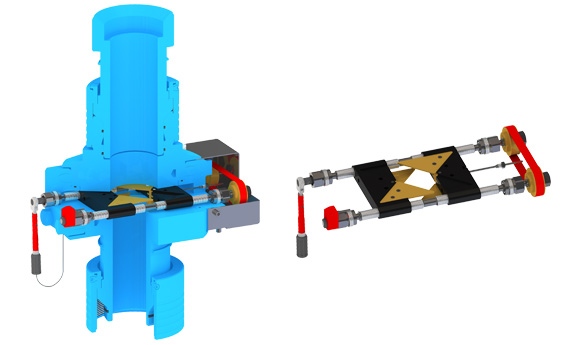

The Phuel Gripper Sub has been specifically designed to prevent this stripping action. Situated directly above the BOP, it’s designed & tested to securely anchor/grip the wire preventing any movement ensuring the integrity of the barriers are maintained.

Phuel has designed the Sub to be compact, allowing it to fit through Rig hatches. We have also incorporated a ‘Quick Test Facility’ to increase its functionality.

When needed the operation of the Gripper is very simple, once the barriers have been set, pressure bled off, the Gripper is closed manually on the stationary wire, that’s it, the wire and Tool String are securely anchored.